Power Analysis Detects Subtle Faults in Products

Power analysis is essential to quality assurance in production testing for a wide variety of electrical products. Power analysis (including harmonics and %THD) of a product is an excellent quality indicator of product performance, especially when compared to an identical model.

For example, consider a medical device like an I.V. infusion pump generating excessive internal heat. A slightly binding rotor bearing or faulty power supply component may allow the product to perform in the short term, but product failure is inevitable. In more subtle failure modes, just because the motor “runs” or the product appears normal doesn’t mean thermal runaway and product failure won’t happen soon. A given product may be meeting its’ basic specifications for operation yet consuming 10% more power than normal.

Power analysis detects otherwise invisible secondary product problems so you can avoid more costly product field failures and improve your product’s reliability reputation.

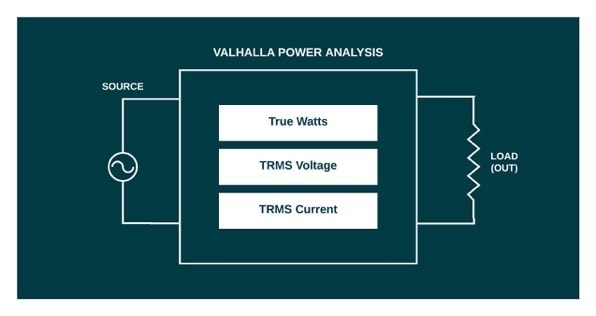

The figure above shows a typical device under test (DUT) being tested for power, current use and voltage drop.

Products Improved through Power Analysis

- AC or DC Power Sources

- Appliances – Toasters, Blenders, TVs

- Battery Powered Devices – Laptops, Green PCs

- Compressors, Elevators, Hoists

- Displays and Monitors (VGA)

- EnergyStar Program Product Power Analysis

- Fluorescent Lamps

- Generators – AC or DC

- Gyro’s (inertial Guidance System’s)

- High Intensity Discharge Lamps

- Lamp Ballasts, Compact and Magnetic

- Lamps, Light Bulbs

- Laser Printers, Faxes, Office Equipment

- Linear Mode Power Supplies

- Medical Instruments, I.V. Pumps

- Motor Incorporated Products, 1Ø & 3Ø

- Power Tools – Drills, Saws, Lathes

- Pumps, Liquid and Vacuum-Type

- Switching Mode Power Supplies

- Test Instruments

- Transformers – all 1Ø and 3Ø types

- Transformer Incorporated Products

- Uninterruptible Power Supplies